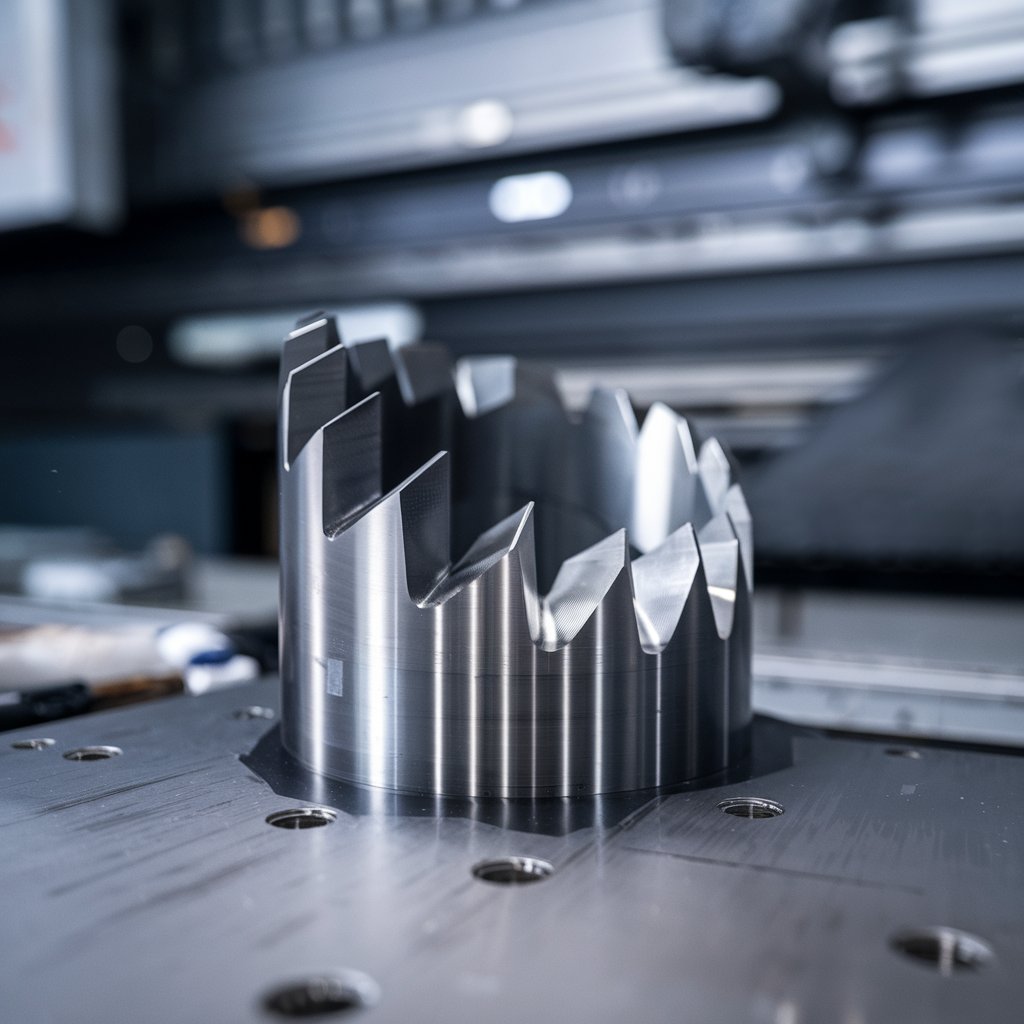

Modern machining would benefit much from the 45 degree chamfer CNC metal bit. Renowned for its accuracy and adaptability, it lets experts produce useful, aesthetically pleasing, and absolutely necessary for assembly chamfered edges. Whether applied in general, automobile, or aerospace manufacturing, this instrument is indispensable in forming metal component edges.

What Makes the 45 Degree Chamfer Special?

The 45 degree chamfer CNC metal bit is made to produce, on different materials, mostly metals, a 45-degree slanted edge or “chamfer”. These chamfers:

- Eliminate Sharp Edges:Ensuring safety during handling and use.

- Improve Aesthetics:Adding a polished, finished look to metal products.

- Enhance Functionality:Facilitating better assembly by easing edges.

The 45-degree angle is chosen because it strikes a compromise between structural integrity and design. Chamfers also help to lower stress levels, therefore prolonging the lifetime of parts.

How to Use and Measure a 45 Degree Chamfer

Starting with knowledge of its operation and proper measurement, using a 45 degree chamfer CNC metal bit efficiently.

Using the Bit

When creating a chamfer:

- Select the Right Tool:Verify the chamfer bit’s material and intended chamfer size match.

- Adjust the CNC Machine:Specify the toolpath and guarantee correct speeds and feeds.

- Use Cutting Fluids:Particularly with stronger metals like steel, this lower heat and friction when running.

Measuring the Chamfer

To measure a 45-degree chamfer:

- Chamfer Width:Measure the angular edge’s length with calipers.

- Angle Check:An angle gauge or protractor verifies the 45-degree hill.

- Depth Validation:Simple trigonometry allows you to measure the depth to guarantee precision; for a 45-degree cut, the depth equal the width.

Calculating and Programming a 45 Degree Chamfer

Calculating a Chamfer

Knowing how to compute a chamfer guarantees correct arrangement. Applying the formula:

scss

CopyEdit

Depth = Width / tan(45°)

The depth of the chamfer corresponds to its breadth since the tangent of 45° equal 1. For a 5mm chamfer width, for example, a 5mm depth.

Programming the CNC Machine

To program a 45 degree chamfer CNC metal bit:

- Tool Selection:Use a chamfer cutter intended especially for CNC machines.

- Define Parameters:Enter the width and depth of the chamfer depending on computations.

- Run Simulations:Virtual testing of the toolpath helps to guarantee flawless operation and prevent mistakes.

Even in high-volume manufacturing, correct programming provides precision and consistency.

Applications of the 45 Degree Chamfer CNC Metal Bit

This instrument finds use across a wide spectrum including:

- Metal Fabrication:chamfering steel edges for welding ready-made

- Aerospace and Automotive:generating in high-precision components stress-relieved edges.

- Industrial Assembly:guaranteeing improved part fitment by smoothing rough edges.

- Product Design:giving consumer items neat, businesslike finishing.

Chamfered edges enhance shape and function whether you are creating decorative objects or machine components.

How to Chamfer Steel with a CNC Bit

Although it’s a frequent material used in chamfering, steel’s hardness presents difficulties. Here’s how to get a perfect chamfer:

- Use High-Quality Bits:To manage steel’s hardness, choose carbide or HSS chamfer bits.

- Slow Down Cutting Speeds:Reducing speed extends tool life and helps to minimize overheating.

- Apply Cutting Lubricants:These polish the finish and reduce friction.

- Take Multiple Passes:Make slow passes instead of cutting deeply all at once to prevent tool damage.

Although it takes time and the correct tools, steel chamfering results in strong, neat edges.

Chamfer vs. Bevel: What’s the Difference?

Usually used to eliminate sharp edges or prepare components for assembly, a 45 degree chamfer is a smaller, exact cut. Conversely, a 45 degree bevel cut is appropriate for structural or decorative uses since it is deeper and usually covers more space.

Depending on the configuration and toolpath, a 45 degree chamfer CNC metal bit can produce both chamfers and bevels.

Maintaining Your Chamfer CNC Bit

To extend the life of your 45 degree chamfer CNC metal bit, follow these maintenance tips:

- Clean After Use:Remove metal chips and residue.

- Inspect Edges:Regularly check for dullness or damage and sharpen as needed.

- Store Securely:Keep the bit in a protective case to prevent accidental damage.

- Avoid Overloading:Use the appropriate speeds and feeds to avoid excessive wear.

Good maintenance guarantees constant functioning and helps to lower the need for regular replacements.

FAQs

How do you measure a 45 degree chamfer?

Measure width with calipers; check the slope using an angle gauge; make sure depth corresponds with guidelines.

What is a 45 degree bevel cut?

Usually more than a chamfer, a bevel cut is a deeper angled cut across an edge.

How do you program a 45 degree chamfer?

Specify the chamfer path, set tool parameters on the CNC machine, and then evaluate for accuracy using a simulation.

How do you chamfer steel?

Use robust bits, slow down cutting speed, and lubricate for a flawless finish.

Conclusion

The 45 degree chamfer CNC metal bit is a basic instrument for producers looking for accuracy and efficiency as well as machinists. This instrument shows its adaptability in many uses whether used to chamfer steel for durability, enhance part assembly, or provide aesthetic value.

Modern machining depends on the chamfer bit as, with correct use, calculation, and maintenance, it guarantees excellent results.